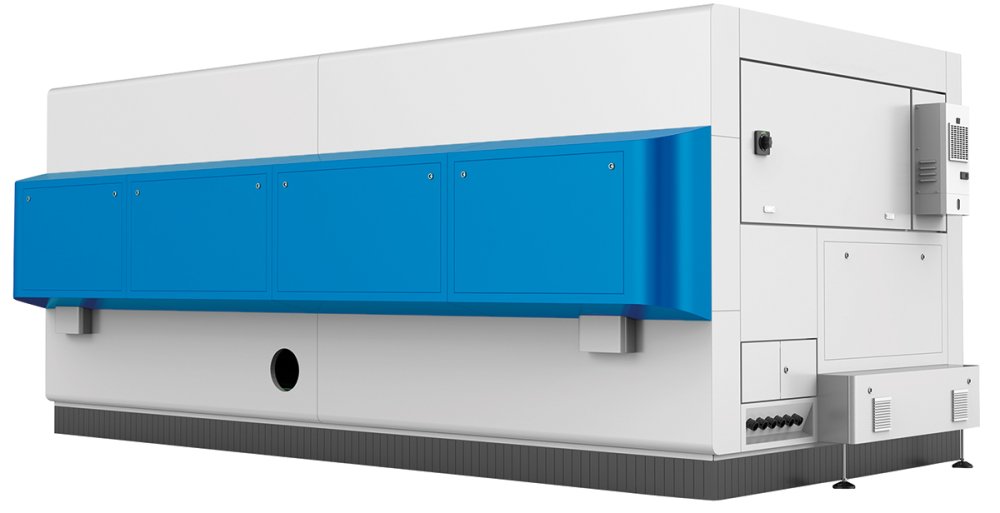

Knuth ACE.Laser ST 3015 1.5R Advanced Laser Cutting System 3000 x 1500 mm Work Area (SKU : 141200)

Knuth ACE.Laser ST 3015 1.5R Advanced Laser Cutting System 3000 x 1500 mm Work Area (SKU : 141200)

Delivery lead times 8/9 months currently

Highlights

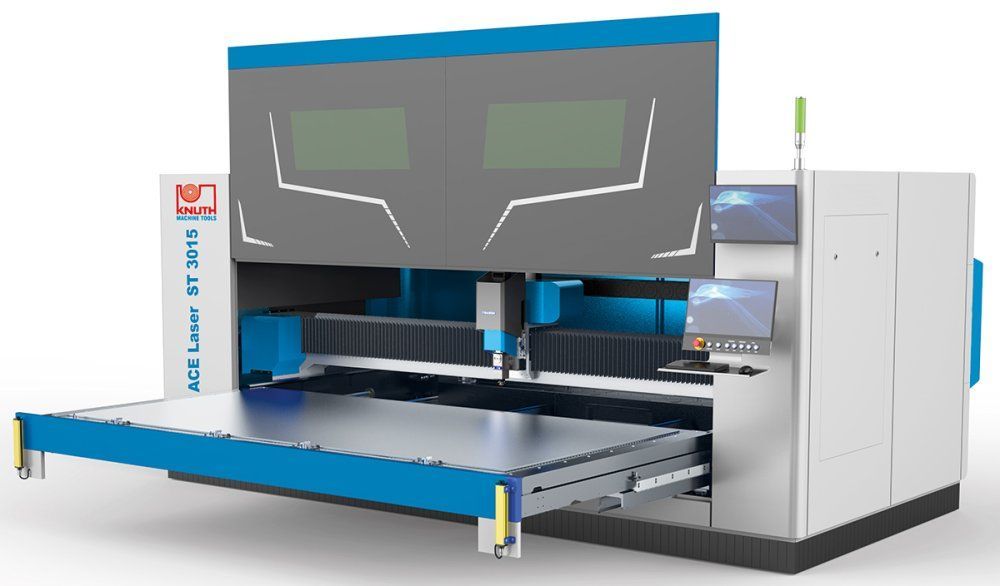

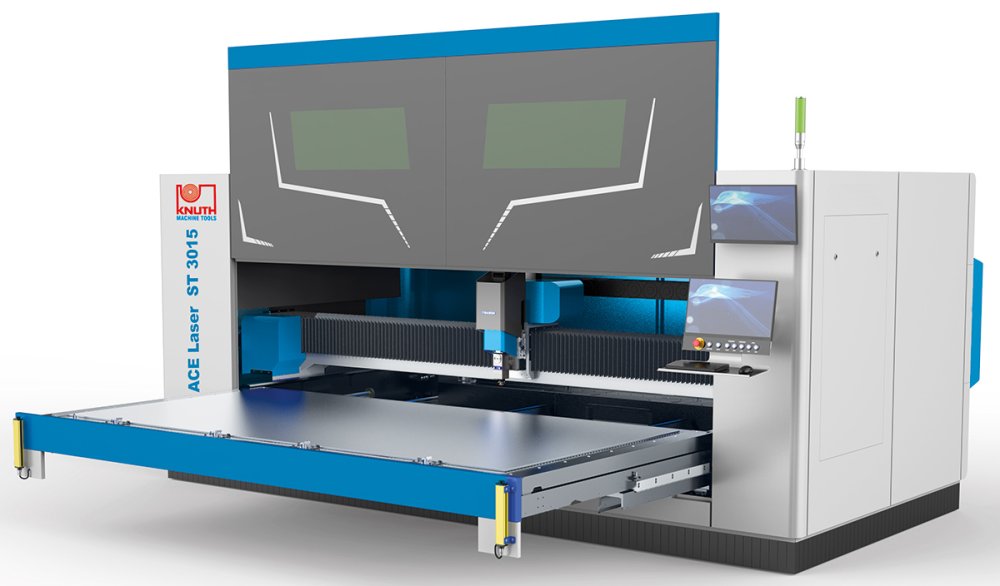

The ACE.Laser ST series consists of advanced cutting systems that allow machining of large metal sheets in small spaces. All components are field tested and tuned perfectly for the cutting process. The machine configuration includes the complete cutting package with filtered vacuum exhaust. The pull-out table allows quick loading and unloading without taking up much space. These characteristics make the ACE-Laser the first choice for industrial laser cutting applications - from complex workpieces with lot size 1 to large-scale series productions in the electronics, aerospace or automobile industries.

- Compact design, long service life and excellent beam quality

- Retractable cutting table for easy loading and unloading

- Complete cutting package with filter extraction system

- Comprehensive KNUTH service: installation, commissioning and maintenance

Product Detail

- This state-of-the-art laser cutting system features a large 3000 x 1500 mm work area and fiber laser sources with 1500 to 6000 Watt beam power

- For loading and unloading the work table can be pulled out from the machine’s full enclosure

- The work table is mounted on a heavy-duty pull-out mechanism and easily can hold loads up to 1000 kg in the fully extended position

- The torsionally rigid gantry spans across the long side of the work table and is moved synchronously on both sides

- The machine meets perpendicularity or squareness tolerances for laser cutting acc. to DIN EN ISO 9013-1

- The machine frame is made of a heat treated weldment ensuring tension-free construction and long-term repeatability for all cut parts

- The precision linear guides require minimal maintenance and are designed for long-lasting precision and high cutting speeds

- High-precision rack-and-pinion gears on the X and Y axis ensure superior and reliable positioning accuracy

- Feeds are driven by powerful servo-motors ensuring high dynamics and exact implementation of technology parameters for superior cut quality of delicate contours and maximum productivity when working with large parts

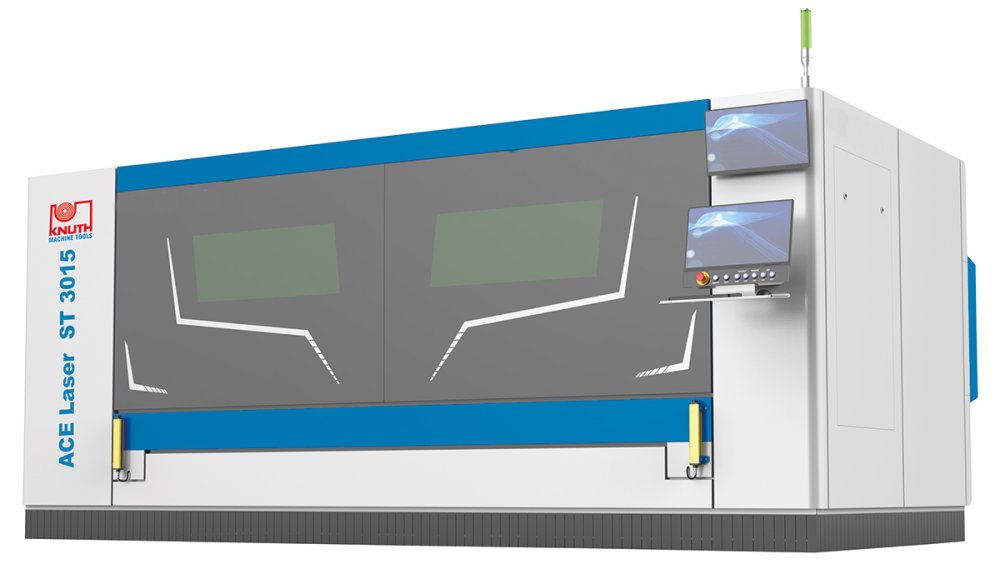

- To ensure operator and environment safety the cutting system is totally enclosed, and a custom safety glass window provides a clear view to observe the cutting process inside the machine

- A hand-held control is included for quick and easy machine setup

- The machine includes a high-performance CNC system with large display and intuitive user interface

- All machine functions are centrally displayed and the user-friendly design ensures short training periods

- An additional monitor is provided for monitoring loading and cutting processes via integrated video cameras

- Remote access to the control for diagnostic and maintenance purposes is possible via an Ethernet interface

- Proportional valves regulate the gas pressures (set in the control) during the cutting process.

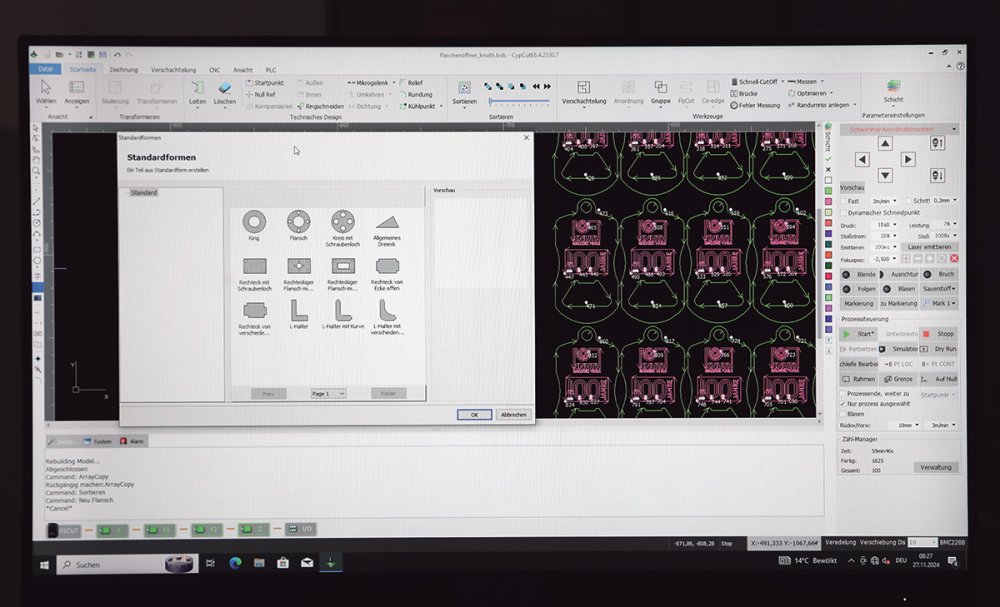

- CypCut is a powerful Nesting and Cutting Software that supports all common file formats (Ai, DXF, PLT, LXD)

- A technology database includes cutting parameters and predefined cycles for various metals

- Automatic nesting saves much time, allows custom adjustments, and ensures optimum material utilization

Control

Nesting Software

- Models with up to 4 kW beam power are equipped with the proven RayTools cutter head, and 6 kW models use the BOCI BLT cutter head

- All models feature an integrated collision guard, automatic focus positioning and height control

- The laser beam focus continuously adjusts itself based on material conditions during program execution

- Features a low maintenance design for quick and easy servicing

- Raycus fiber lasers provide superior electro-optic conversion efficiency, high beam quality, high energy density, and wide modulation frequency

- The long lasting maintenance-free laser source reduces maintenance and operating cost

- A water cooling system ensures optimum temperature balance and protects thermally exposed components in the production environment

- The ACE.Laser ST series includes a powerful filtered vacuum exhaust that is matched to the laser source power

- This highly efficient filtered exhaust system removes particles and fumes generated during production protecting operator health, ensuring high product quality and long machine life

Cutting head

Laser source

Vacuum exhaust

Technical Detail

| Working area | |

|---|---|

| Table dimensions | 3000 mm x 1500 mm |

| Workpiece weight (max.) | 1000 kg |

| Travels | |

|---|---|

| Travel X-axis | 1530 mm |

| Travel Y-axis | 3050 mm |

| Travel Z-axis | 100 mm |

| Rapid feed | |

|---|---|

| Rapid feed X-/ Y-axis | 80 m/min |

| Z-axis rapid feed | 40 m/min |

| Accuracies | |

|---|---|

| Positioning accuracy | 0,03 mm/m |

| Repeatability | 0,03 mm/m |

| Laser | |

|---|---|

| Fiber laser | 1500 W |

| Shaft length | 1,08 ± 10% µm |

| Beam power max. | 1500 W |

| Power consumption | 5,3 kW |

| Cutting capacity in structural steel | 12 mm |

| Cutting capacity in stainless steel | 4 mm |

| Cutting capacity in aluminum | 3 mm |

| Drive capacity | |

|---|---|

| Machine drive capacity X-axis | 1,7 kW |

| Machine drive capacity Y-axis | 2,4 kW |

| Machine drive capacity Z-axis | 0,4 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 4,75 m x 2,26 m x 2,1 m |

| Weight | 5250 kg |

Standard Equipment

CypCut CAD/CAM Software

SKU: 913401

- CAD/CAM Software wich provides all the necessary features and tools to manipulate your design

- Includes drawing import and editing, nesting, path generation and realtime process control

Optional Equipment

( Enquire for details )

Shipping

Fully inclusive shipping rates covering transportation , import customs documentation, duties quoted

for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands and other remote

sites should seek advice prior to order via email. Clients will be responsible for their own site offload

and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.

Other Models In The Extensive Laser Cutting Systems Range From Knuth

Get in touch

We will get back to you as soon as possible

Oops, there was an error sending your query.

Please try again later