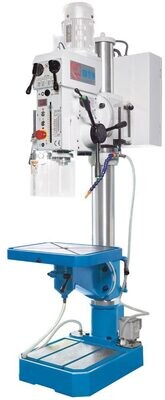

Knuth FPK 6.3 Tool Milling Machine ( Part No. 302341) The modern generation of tool milling machines

Knuth FPK 6.3 Tool Milling Machine

( Part No. 302341 )

The modern generation of tool milling machines

Availability. Currently 4 weeks from receipt of order. Subject to no prior sales.

Highlights

Knuth FPK 6.3 Tool Milling Machine

This versatile tool-milling machine has become an indispensable part of mechanical production in tool and mold making. The compact design, which offers a lot of flexibility and at the same time is very easy to use, has proven itself many times and has been interpreted in a modern way. Servo drives and ball screws make the machine even more powerful and precise. The entire series is ideally suited for the construction of tools and molds in repair shops as well as training and manufacturing departments.

- Vertical and horizontal spindle

- Precise preloaded ball screws on all axes

- Large vertical console and work table

- Automatic feed on all axes with rapid feed

- Infinitely variable main spindle drive

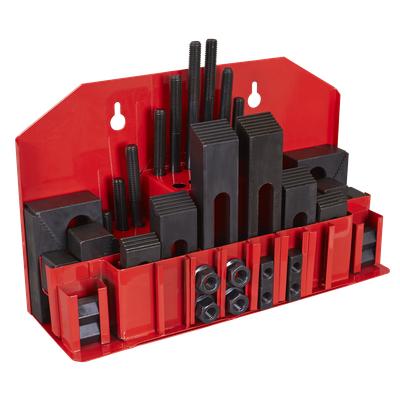

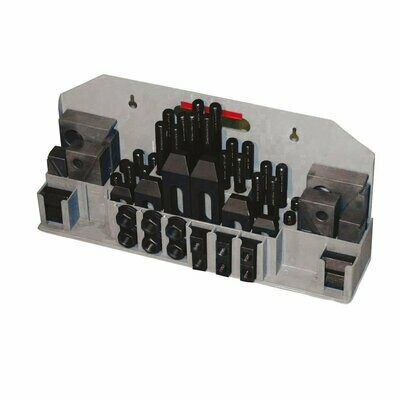

- Extensive accessory package included

Details

- The Machine column made of premium cast-iron, ensures maximum dynamic rigidity and constant precision

- Precision preloaded ball screws on all axes

- Ergonomically arranged controls and a swivelling control panel plus standard digital position indicator for maximum operator comfort

- Both machines have rigid outer arbors for horizontal milling

- Despite the compact design, this machine features a large work table and large travels for versatile use

- Automatic feed on all axes, infinitely variable and with fast rapid feed

- The vertical cutter head swivels and the quill can be moved manually

- The infinitely variable main spindle drive with counter gear offers a wide speed range with high torque

- Extensive accessory package included

- Central lubrication system is standard equipment

- Price incl. fully assembled 3-axis position indicator

Technical Details

| WORKING AREA | |

|---|---|

| Table dimensions | 450 mm x 850 mm |

| Vertical table | 250 mm x 1190 mm |

| Table load capacity (max.) | 300 kg |

| Number of T-slots | 7 positions |

| T-slot (width x spacing) | 14 mm x 63 mm |

| T-slots, vertical table (number) | 3 positions |

| TRAVELS | |

|---|---|

| Travel X-axis | 600 mm |

| Travel Y-axis | 450 mm |

| Travel Z-axis | 450 mm |

| VERTICAL MILLING SPINDLE | |

|---|---|

| Travel pinole | 100 mm |

| Spindle center - column (min.) | 165 mm |

| Spindle center - column (max.) | 665 mm |

| VERTICAL MILLING HEAD | |

|---|---|

| Angular adjustment of vertical head | ± 90° |

| RAPID FEED | |

|---|---|

| Rapid feed X-axis | 1200 mm/min |

| Rapid feed Y-axis | 1200 mm/min |

| Rapid feed Z-axis | 1200 mm/min |

| FEED | |

|---|---|

| Work feed X-axis | 10 mm/min - 1000 mm/min |

| Work feed Y-axis | 10 mm/min - 1000 mm/min |

| Work feed Z-axis | 10 mm/min - 1000 mm/min |

| HORIZONTAL MILLING SPINDLE / VERTICAL MILLING SPINDLE | |

|---|---|

| Speed range | 40 1/min - 2000 1/min |

| Spindle mount | ISO 40 |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 5,5 kW |

| Motor rating coolant pump | 0,09 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 1,6 m x 1,8 m x 2 m |

| Weight | 1750 kg |

Standard Equipment

- electronic hand-wheels

3-axis position indicator

central lubrication

reducing sleeves MT1, MT2, MT3

collet chuck with collets

horizontal milling arbor 16mm

horizontal milling arbor 22mm

cutter arbor, long, 27 mm

horizontal milling arbor 32mm

Counterholder for horizontal milling

chip tray

coolant system

work lamp

pull rod (M16) for horizontal / vertical spindle

levelling pads and bolts

operating tools

operator manual

Options

Wide range of tooling options available

Please contact us by email if you need pricing information on any tooling optional equipment.

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.