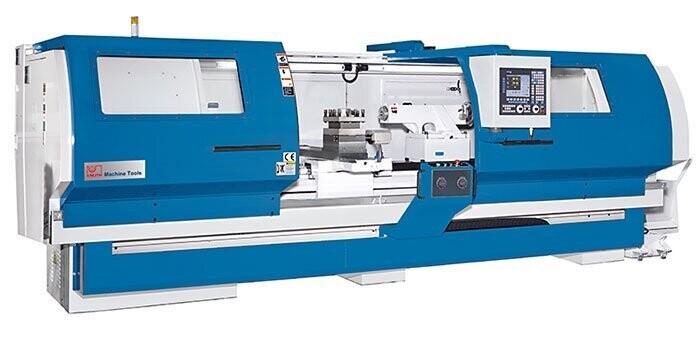

Knuth Forceturn 630.30 CNC Flat Bed Lathe (Part No. 100351 ) High Performance Lathe with easy handling & a centre width of 3000 mm

Knuth Forceturn 630.30 CNC Flat Bed Lathe( Part No. 100351 )

High Performance Lathe with easy handling & a centre width of 3000 mm

Availability, Currently 6 Months Lead Time To Site, Subject To No Prior Sales.

Highlights

Forceturn Series Lathes

Our Forceturn series is the optimal solution for customers who want to machine large parts with a powerful CNC lathe. The robust flat bed design ensures high precision when machining heavy workpieces that can be up to 5,000 mm (197 in) long. The control is easy to use and has a teach-in function. Thanks to the two electronic handwheels, the machine can be operated in a similar way to a manual lathe. Options allow adaptation to special requirements. This makes the Forceturn series the best choice for maintenance departments or single part production.

- Powerful main drive for heavy machining

- Servo driven 4 station turret

- 2 electronic hand-wheels for manual operation

- Cycle programming for batch production

Knuth Forceturn 630.30 CNC Flat Bed Lathe

- Highlights

- Fagor 8055i A-TC featuring intuitive, easy to learn cycle programming, including Profile Editor, for batch and single part production of complex workpieces

- Graphical simulation for added safety

- 2 electronic hand-wheels at the control panel for manual operation and for easy, quick setup of new workpieces and tools

- Lots of experience went into the design and construction of this machine bed featuring large guides that are hardened, ground and counter-laminated

- Powerful main drive motor handles part weights up to 1,7 t with ease

- A high-performance coolant system and automatic central lubrication system are included

- Spindle bore 85mm (models 630) or 105mm (models 800)

- Infinitely variable, programmable, and adjustable spindle speeds with automatic 3-step main gear

- Motor power 15/22 kW

- Heavy, automatic 4-station servo-driven tool changer for programmed tool changes

Controls & Software

Fagor 8055i FL-TC control

- The FAGOR 8055 Numeric Controls are user-friendly and easy to handle

- A graphical Profile Editor is available to facilitate contour input. The contour to be produced can easily be created by using the information from parts drawings

- The graphically displayed cycles can be used individually or they can be linked within a user application

- The Fagor 8055i/A Version TC Cycle Control is a powerful CNC, specifically designed for the most demanding machine tool applications. Its calculation capacity and high speed ensure maximum power and increased programming flexibility.

- Profile Editor

- DIN ISO programming is also possible

- Fixed cycles with options for graphic geometry definition

- With multi-threaded thread cycle

- Thread repair with cycle

- Graphic simulation with solid body display, including simultaneous for editing

- Easy to use tool management

- USB port

- RS232 port

- Look Ahead function (75 blocks)

- Block Processing Time: 1.5 ms

- Compact Flash with storage expansion up to 2 GB

- Optional C axis function prepared for lathes

- Optional up to 1 MB RAM user memory

- Optional free M-Codes, inputs and outputs

Technical Details

| WORKING AREA | |

|---|---|

| Turning diameter over bed | 670 mm |

| Bed width | 450 mm |

| Center height | 335 mm |

| Turning-Ø over support | 400 mm |

| Workpiece length (max.) | 3100 mm |

| TRAVELS | |

|---|---|

| Travel X-axis | 450 mm |

| Travel Z-axis | 3000 mm |

| HEADSTOCK | |

|---|---|

| Speed range | 27 1/min - 2250 1/min |

| Spindle mount | D1-8 |

| Spindle bore | 85 mm |

| RAPID FEED | |

|---|---|

| Rapid feed X-axis | 5000 mm/min |

| Rapid feed Z-axis | 5000 mm/min |

| TOOLING | |

|---|---|

| Number of tool stations | 4 positions |

| ACCURACIES | |

|---|---|

| Positioning accuracy X-axis | 0,015 mm |

| Positioning accuracy Z-axis | 0,02 mm |

| Repeatability X-axis | 0,007 mm |

| Repeatability Z-axis | 0,01 mm |

| TAILSTOCK | |

|---|---|

| Tailstock taper | 5 MT |

| Tailstock quill diameter | 105 mm |

| Tailstock quill stroke | 170 mm |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 22 kW |

| Main drive, continuous load | 15 kW |

| Motor rating X-axis | 2 kW |

| Motor rating Z-axis | 3,6 kW |

| Total power consumption | 40 kVA |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 5,5 m x 2,25 m x 2,25 m |

| Weight | 5600 kg |

Standard Equipment

fagor 8055i FL-TC control

2 electronic hand-wheels

3-jaw chuck Ø 300 mm

automatic 3-step gears

4-station servo tool holder

coolant system

central lubrication

tailstock

work lamp

operating tools

operating manual and programming instructions

Optional Equipment

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.

The certificate holder's Management System corresponds to standard ISO 9001:2015.