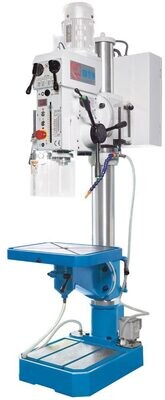

Knuth KB 1400 Bed Type Milling Machine ( Part No. 301320) High capacity bed type milling machine for large parts and heavy machining

Knuth KB1400 Bed Type Milling Machine

( Part No. 301320)

High capacity bed type milling machine for large parts and heavy machining

Availability. Currently 26 weeks from receipt of order. Subject to no prior sales.

Highlights

Knuth KB1400 Bed Type Milling Machine

The heavy universal bed-type milling machine offers wide guides and high drive power for superior machining performance and, with its extensive equipment, is ideal for plant and mechanical engineering. The heavy vertical milling head can be swiveled to the right and left, the quill can be moved manually and the spindle speed can be infinitely adjusted. The feed in the Y and X axes can be varied using a robust manual gearbox. All axes have a rapid traverse and the large clamping table offers plenty of space for workpieces and clamping devices.

- Large work area

- Swiveling vertical milling head

- infinitely variable feed

- Extensive standard equipment

Detail

- It is not the machine table (with the workpiece) that is moved in the Z-axis, but the milling head - greater stability and lower vibrations lead to more precision with a very high table load capacity! This effect is additionally reinforced by the large, heavy cast iron frame (Meehanite) and the extremely wide flat guides.

- Stepless speed regulation by frequency converter

- Rigid right-angle guides ensure lasting accuracy

- Meehanite cast iron frame

- Milling head swiveling ± 45°

- Hardened and ground guideways in all axes

- The machine is equipped with a 3-axis position indicator as standard

3-axis position indicator

- Higher work accuracy

- Lower error rate

- Greater production security

- Significant time savings

- productivity increase

- Optimal readable display

- User-friendly functions

- Clearly arranged keyboard

- Resolution 0.01 / 0.005mm

- coordinate value specification

- Retaining the axis position when the display is switched off

- Bolt circle pattern calculation

- calculator function

- Storage for 10 tools

- Radius / diameter switching

- Conversion mm/inch

- Easy attachment and maintenance-free operation

Technical Details

| WORKSPACE | |

|---|---|

| table mounting surface | 1400mm x 400mm |

| T-slots, number | 3 pieces |

| T-slots, width | 18mm |

| T-slots, spacing | 100mm |

| Distance spindle axis - table surface | 150mm - 650mm |

| Height adjustment speed (max.) | 1670mm/min |

| TRAVERSE PATHS | |

|---|---|

| X axis travel | 950mm |

| Y axis travel | 400mm |

| Z axis travel | 500mm |

| VERTICAL MILLING HEAD | |

|---|---|

| Spindle speed (vertical) | 30 rpm - 1800 rpm |

| unloading | 510mm |

| spindle mount | ISO 50 |

| quill stroke | 105mm |

| Swivel range head | ± 45° |

| RAPID TRAVERSE | |

|---|---|

| Rapid X axis | 1670mm/min |

| Rapid traverse Y-axis | 1670mm/min |

| Rapid Z axis | 1670mm/min |

| FEED | |

|---|---|

| Feed rate X-axis increments | 9 |

| Feedrate X axis | 18mm/min - 627mm/min |

| Feed rate Y-axis increments | 9 |

| Y axis feed rate | 18mm/min - 627mm/min |

| Feedrate Z axis | 18mm/min - 627mm/min |

| DRIVE POWER | |

|---|---|

| Main drive engine power | 7.5kW |

| Motor power Z axis | 0.75kW |

| engine power feed | 0.75kW |

| Engine power coolant pump | 0.04kW |

| MASS AND WEIGHT | |

|---|---|

| Dimensions (length x width x height) | 2.29m x 1.77m x 2.12m |

| Weight | 3660kg |

| flow rate, cooling pump | 12L/min |

Standard Equipment

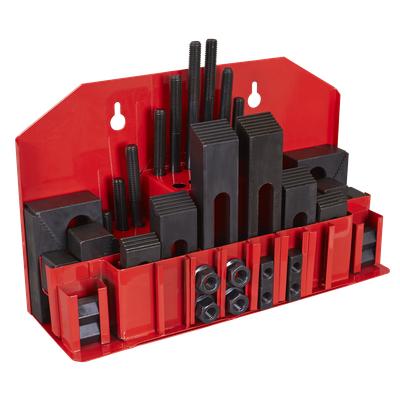

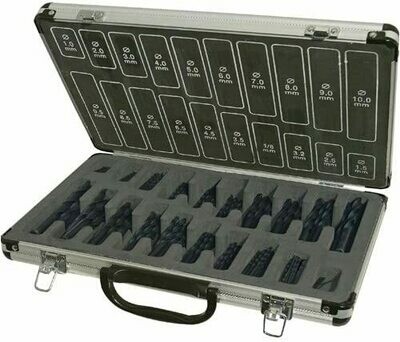

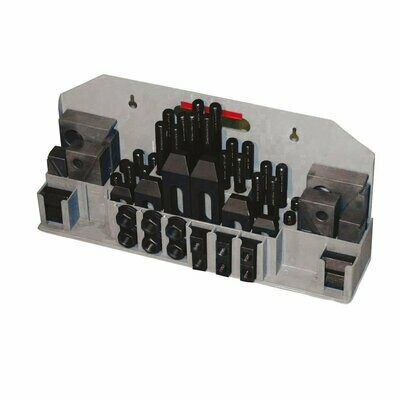

- 3-axis position

display Collet chuck with collets Ø 4,5,6,8,10,12,14,16 mm

Reducing sleeves MT4, MT3 and MT2 Milling arbor

Ø 40 mm

Coolant system

Work light

Central lubrication Operating tools Operating instructions

Optional Equipment

Wide range of tooling options available

Contact us via Email for price details of any tooling options of interest.

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.