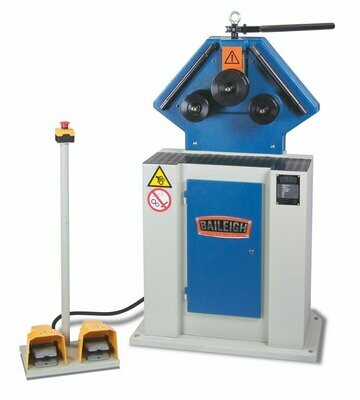

Knuth KRM T 20/4,0 3 Roller Roll Bender ( Part No. 131988) Modern design,user friendly machine with asymetrical mounted rolls

Knuth KRM T 20/4,0 3 Roller Roll Bender

Part No. 131988

Modern design , user friendly machine with asymetrical mounted rolls

Availability. 3 to 4 Months Delivery lead time typical , subject to no prior sales

Highlights

KRM T Series Plate Rolling Machines

KRM is a series of heavier medium capacity round bending machines for workpieces up to 2000 mm (78.74 in.) in length. The machines have a solid, closed machine frame and you can adjust the rear roller manually by hand or optionally with a motor. With special features such as conical bending and pre-bending, the models in this series are suitable for a wide range of applications in individual production.

Range

KRM T 10/4.0 Working length 1050 mm Maximum 4 mm capacity plate bending

KRM T 10/5.0 Working length 1050 mm Maximum 5 mm capacity plate bending

KRM T 12/5.0 Working length 1270 mm Maximum 5 mm capacity plate bending

KRM 15/3.0 Working length 1550 mm Maximum 3 mm capacity plate bending

KRM T 15/4.0 Working length 1550 mm Maximum 4 mm capacity plate bending

KRM T 20/2.0 Working length 2050 mm Maximum 2 mm capacity plate bending

KRM T 20/4.0 Working length 2050 mm Maximum 4 mm capacity plate bending ( Quoted Model)

Knuth KRM 20/4.0 3 Roller Roll Bender

KRM is a series of heavier medium capacity round bending machines for workpieces up to 2000 mm (78.74 in.) in length. The machines have a solid, closed machine frame and you can adjust the rear roller manually by hand or optionally with a motor. With special features such as conical bending and pre-bending, the models in this series are suitable for a wide range of applications in individual production.

- Asymmetrical structure

- Main motor with braking

- Hardened rollers with wire insertion grooves

- Conical bender

- Manual rear roller adjustment (optionally motor-driven)

Detail

- 3-roller roll bender with asymmetrically positioned rollers

- Rigid, seamless machine frame made of ductile cast-iron

- Hardened rollers, suitable for stainless steel

- Main motor with brake system for exact bending

- Pull-out top roller with eccentric lock and safety switch

- Bottom and rear rollers feature wire insertion grooves

- Conical bending feature is included in standard equipment

- Hand wheel for rear roll feed

- Quick adjusting rolls (motor-driven, option)

- Mobile control panel with foot switch for left/right rotation

Technical Details

| Working area | |

|---|---|

| Working length | 2050 mm |

| Plate thickness (max.) - 450 N/mm² | 4 mm |

| Plate thickness(max.) - 700 N/mm² | 2 mm |

| Max. plate thickness for conical bending | 2,5 mm |

| Roll diameter | 140 mm |

| Roller speed | 3,5 m/min |

| Wire grooves diameter | 4/7/9/13 mm |

| Drive capacity | |

|---|---|

| Motor rating main drive | 2,2 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 3,2 m x 0,75 m x 1 m |

| Weight | 1650 kg |

Standard Equipment

Optional Equipment

Tooling options available

Contact us via Email for price details

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.

.