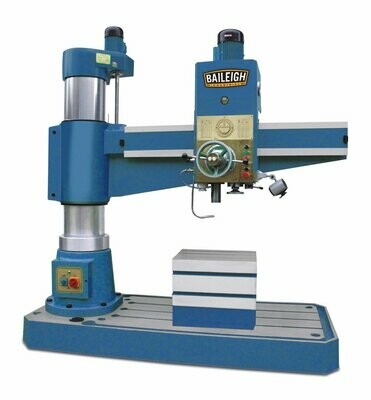

Knuth KSR 50 VT Servo Conventional High Speed Drill Press ( Part No. 162365 ) The first servo conventional high speed radial drill press.

Knuth KSR 50 VT Servo Conventional

High Speed Drill Press

( Part No. 162365)

The first servo conventional high speed radial drill press.

Ex Stock Availability, 4 weeks . Subject to No Prior Sales.

Highlights

- Drilling capacity 50 mm

- Tapping capacity, steel M 32

- Table set up area 1.200 x 505 mm

Details

- Table, column, male die and gear head are made of thick-walled high-grade cast-iron and the entire machine structure features high-quality components and precision machined surfaces

- The large work area can be expanded by mounting optional swivel and angle tables for a wide variety of clamping and machining options

- The male die features a low-maintenance, very rigid design and runs smoothly in two large linear roller guideways, allowing exact positioning with minimal effort

- The entire machine is extremely smooth running for effortless operation in a production environment

- Column and male die are equipped with hydraulic clamping fixtures

- Main spindle drive with 2 gear steps, infinitely variable speed in each gear step

- For angular bores, the drill head can be rotated 45° in either direction

- A central lubrication system simplifies maintenance

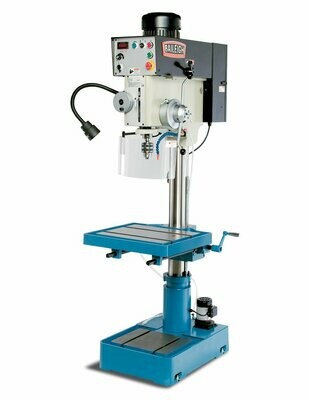

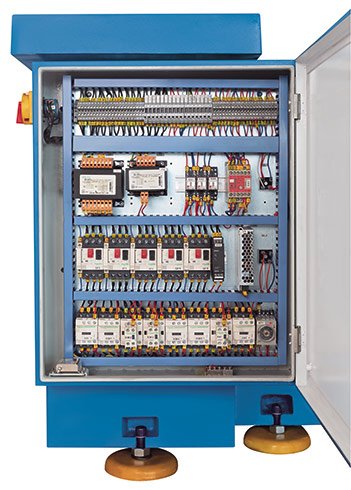

Electronically controlled servo quill feed

- A servo-motor provides infinitely variable control of the quill feed

- The depth stop is set electronically with a positioning accuracy of +/- 0.1 mm

Improved functionality and improved layout of the large touchscreen display

- All machine functions are controlled and displayed on the touchscreen

- Measuring units for input and display can be selected by the operator (mm or inch)

- In Thread Cutting Mode, the quill will automatically reverse direction upon reaching the selected thread depth

- Various alarm screens warn the operator in case of operational errors and display information on the operational state

- The control software also provides recommendations for rpm and feed in relation to the desired drill size

- The high-performance coolant system is activated at the touchscreen

Technical Details

| Drilling capacity | 50 mm |

| Tapping capacity, steel | M 32 |

| Throat | 640 mm |

| Spindle nose-to-table surface distance | 760 mm |

| Head swivel range | ± 90° |

| Column diameter | 220 mm |

| Table set up area | 1.200x505 mm |

| Column stroke | 400 mm |

| Quill stroke | 200 mm |

| Upper beam travel | 590 mm |

| Spindle mount | 4 MT |

| Spindle speed (infinitely variable) | 50 - 2.000 1/min |

| Feeds | (6) 1 - 3.000 mm/min |

| Motor rating main drive | 3 kW |

| Motor rating height adjustment | 1,5 kW |

| Motor rating feed | 1,26 kW |

| Motor rating hydraulic pump | 0,37 kW |

| Motor rating coolant pump | 0,085 kW |

| Supply voltage | 400 V |

| Overall dimensions (length x width x height) | 1,72x1,2x2,25 m |

| Weight | 2.740 kg |

| Part No. | 162365 |

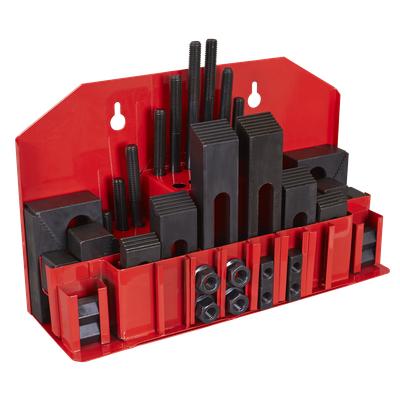

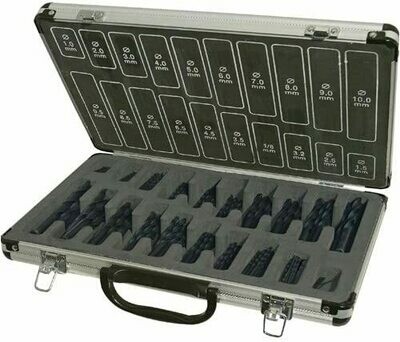

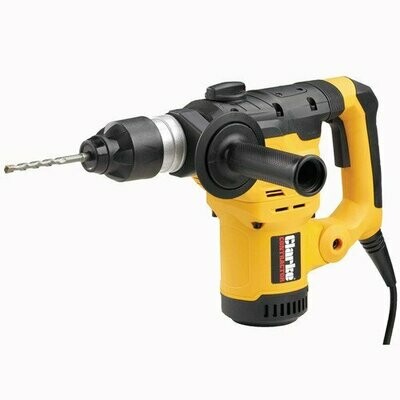

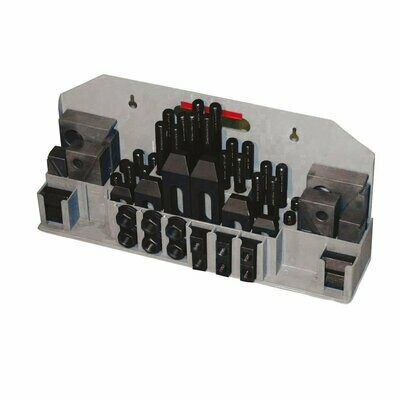

Standard Equipment

- touch screen monitor

- additional setup areas at the side and rear

- cube table

- swivelling horizontal table

- work lamp

- coolant system

- tapping unit

- reducing sleeves

- operating tools

- operator manual

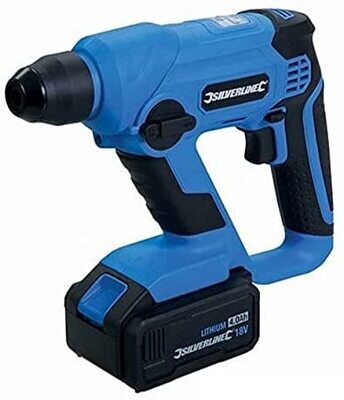

Options

Wide range of tooling options available

Contact us via Email for price details

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.