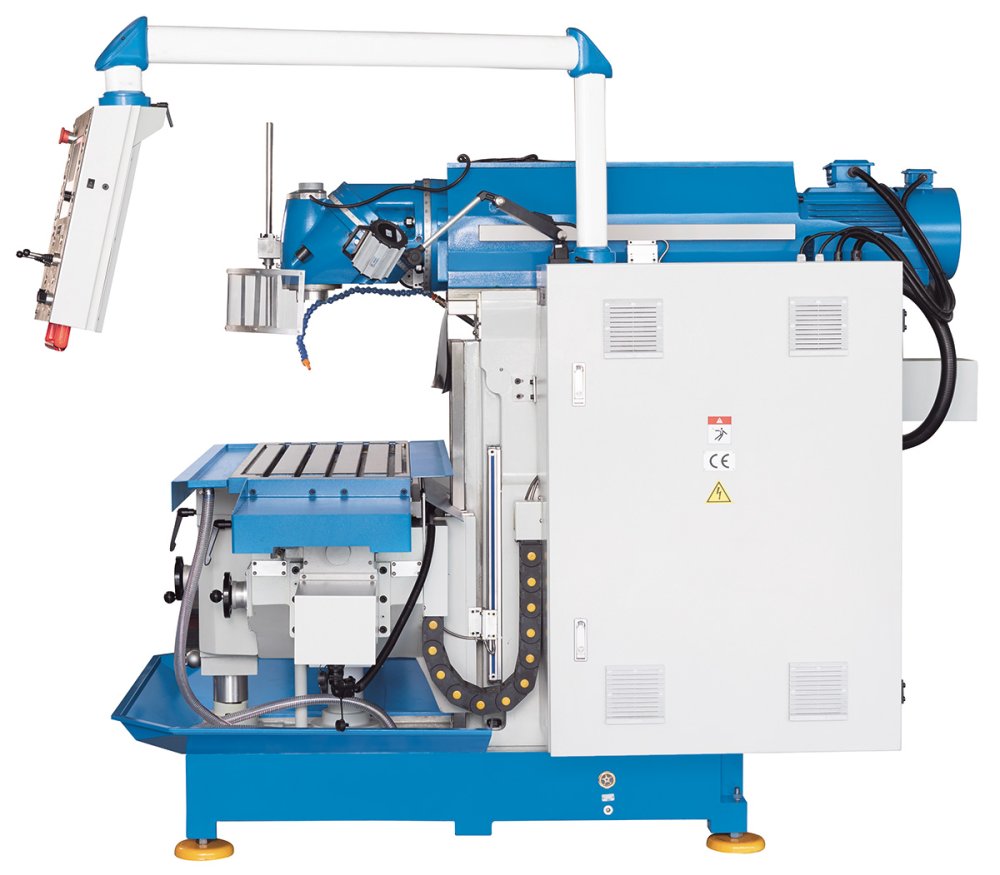

Knuth Servomill® UWF 900 Servo Conventional Universal Milling Machine SKU : 301290

Knuth Servomill® UWF 900 Servo Conventional Universal Milling Machine

( Part No. 301290)

Servo- conventional drive technology- rigidity,flexibility and large workspace

Availability. Currently 4 weeks from receipt of order. Subject to no prior sales.

Highlights

Servomill UWF Series Universal Milling Machines

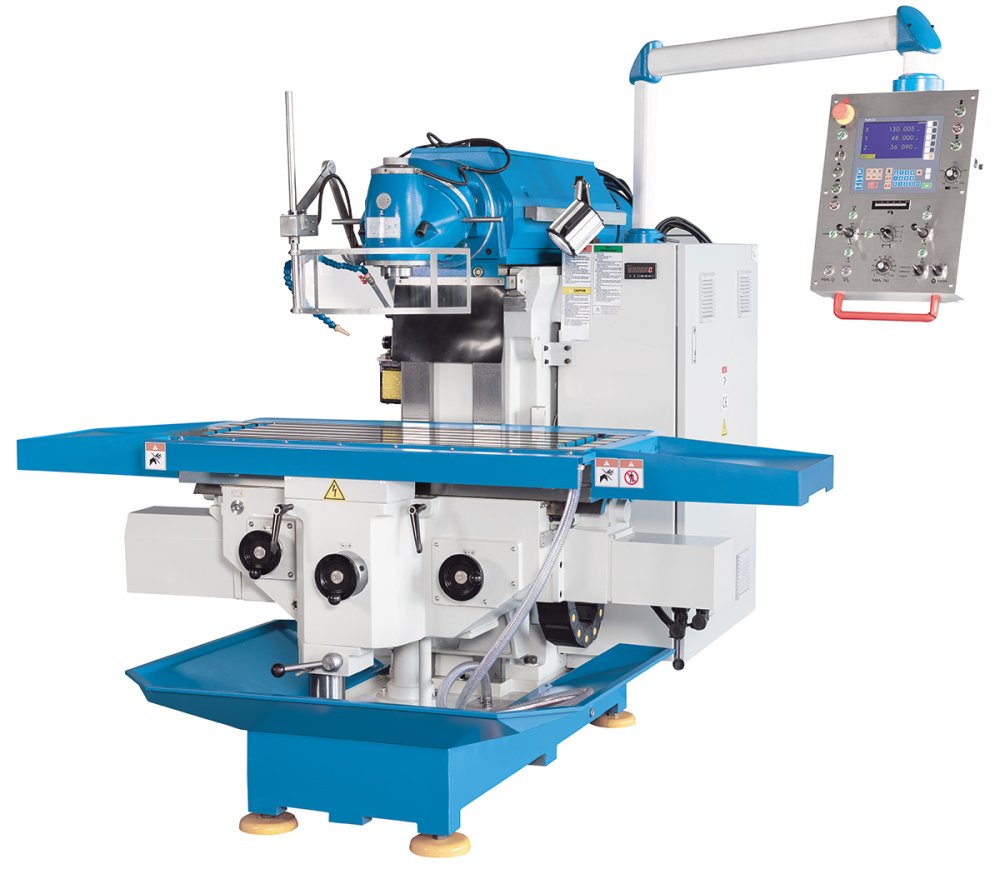

The versatile Servomill UWF with servo-conventional feed technology and on two levels swiveling cutter head is the top model of the Universal Milling Machine series. This series features an extra large work area and more powerful main spindle drives. Electronic stops, electronic hand wheels and additional milling functions give the Servomill many of the advantages of the CNC series production technology even without programming. These machines are mainly used in tool making, manufacturing and training.

- Large work area

- Servo-conventional feed technology

- Preloaded ball screws on all axes

- Electronic hand-wheels

- Universal cutter head with 2 swivel axes

- Infinitely variable spindle speed

Range

Servomill UWF 900 1235 X 460 TABLE 7.5 KW DRIVE ( Quoted Model )

Servomill UWF 1200 1600 X 500 TABLE 11 KW DRIVE

Servomill UWF 1400 2000 X 500 TABLE 11 KW DRIVE

Details

Servomill UWF 900 Universal Milling Machine

Integrated electronics allow for easier, more precise and more efficient conventional milling

- Servomill machines represent a new generation of conventional milling machines

- All Servomill models feature a user-friendly design, significantly higher precision and increased productivity

- Very high reliability and long service life of all components ensure drastically reduced maintenance and increased availability

- The Servomill UWF series machine frame features a very sturdy and torsionally rigid construction with knee-and-column design

- A large setup area and long travels result in a large work area despite the compact overall dimensions

- The console is supported by an additional guide system for increased table load capacity

- The work table moves on the X axis in a large dimensioned dovetail guide, which features excellent damping properties and can be adjusted with very high precision

- The box ways have wide support bases for increased load capacity and maximum dimensional stability while guiding console and top beam

- All guides are hardened and ground, and lubricated via a central lubrication system

- The complete drive is integrated in the heavy top beam that positions the cutter head

- This design ensures efficient power transmission with quiet, low vibration operation and features a very long Y axis travel

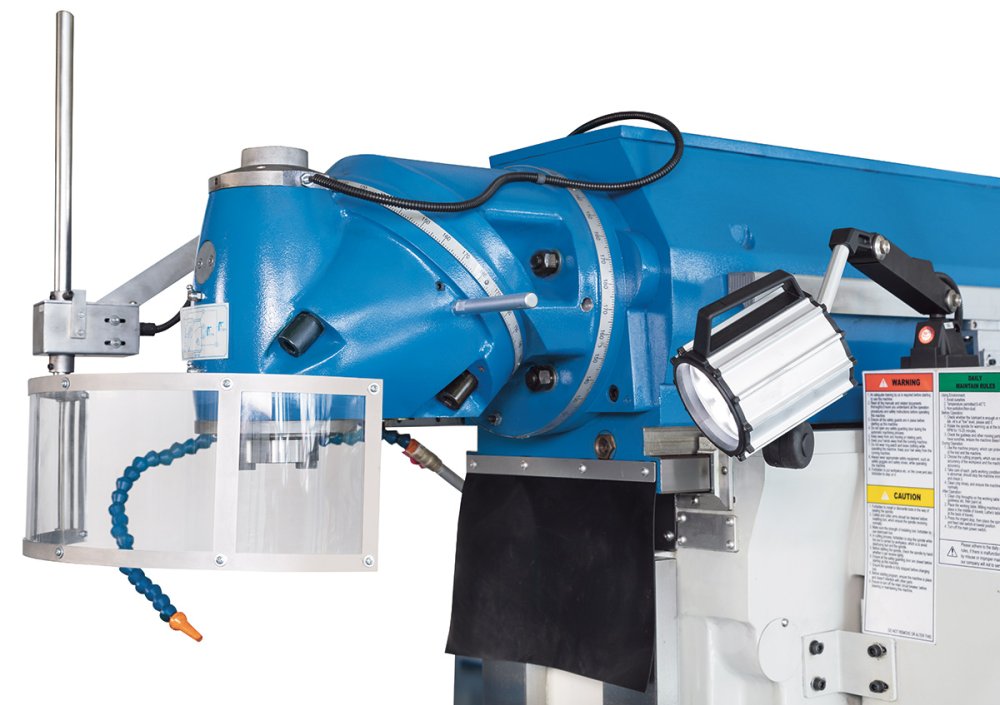

- Another highlight of this series is the universal cutter head that swivels on 2 axes

- Cutter spindle can be moved to virtually any spatial angle and quickly moved to the horizontal plane

- The robust 2-step gears are hardened and ground and feature an infinitely variable wide speed range, high load capacity, and quiet operation

- Powerful servo motors allow infinitely variable feed speeds and rapid feeds on all axes

- Preloaded ball screws on all axes ensure precise, jolt- and backlash-free positioning with minimal wear for a long tool life

- The machines’ standard equipment includes extensive accessories, including a powerful coolant system, LED work lamps, and a wide selection of operating tools

Servomill - Highlights

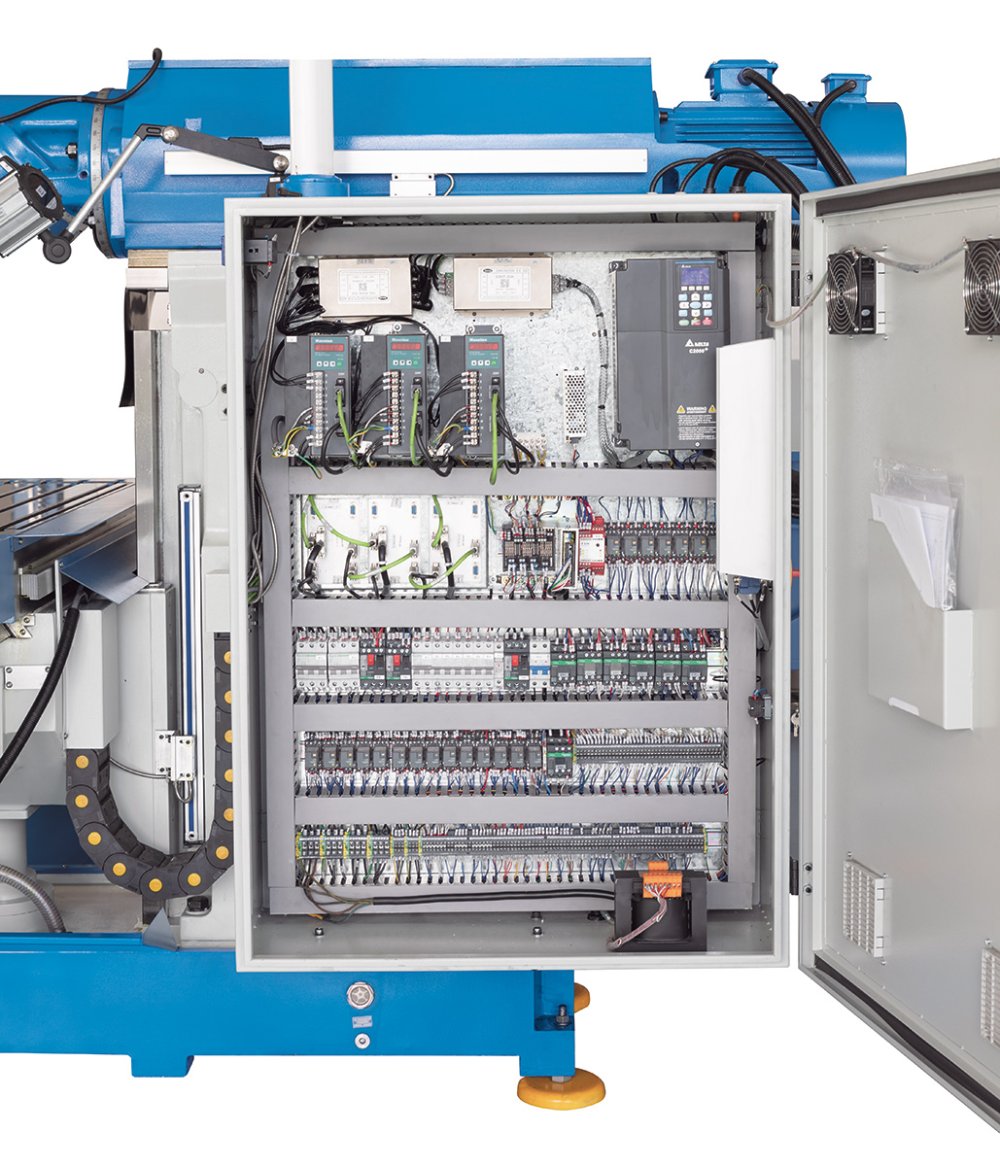

- Electronics developed and built in Germany

- Positioning control for traveling pre-selected paths on all axes

- Zero backlash preloaded ball screws

- Servo-motors on all axes, infinitely variable feed, rapid feed, and speed control

- Electronic spindle load indicator

- Electronic hand-wheels on all axes

- X, Y and Z axis movement via joystick technology

- Integrated position indicator with precision glass scale

- Feed can be synchronized with the spindle speed

- Powerful servo motors allow infinitely variable feed speeds and rapid feeds on all axes

Your Advantages:

- Easy to use: intuitive operation - practical layout of control elements and streamlined function

- Automatic feed on all axes and infinitely variable rapid feed

- With speeds up to 5000 mm/min

- Set limit stops on any axis with the push of a button - 3 stop positions per axis can be stored

- More precise: operated via electronic hand-wheels - axes are powered by high-quality servo drives that translate your hand movements with the precision and dynamics of modern CNC machines

- More reliable: drives, spindles, and measuring systems are totally enclosed or mounted in protective enclosures and virtually maintenance-free

- Electronics - made in Germany

- More capacity: this machine only uses premium drive components that are designed for continuous operation

- Maintenance-free: no regular maintenance needed for the entire feed drive

- Advanced Feed Technology:

- Axes are powered by high-quality servo drives that translate your hand movements with the precision and dynamics of modern CNC machines

- Reliable, maintenance-free mass production technology

- High rapid feed rate for reduced machine down-times

- Ball screw drive on all axes:

- Considerably less errors due to loseness (backlash), resulting in significantly higher precision

- Significantly reduced friction, no stick-slip effect, reduced heat buildup, minimal wear

- Electronic hand-wheels:

- Micro-control via electronic hand-wheels offering the same handling and postioning as with a conventional machine, just smoother and more precise

- Joystick control:

- Maximum operator comfort for axis movements

- Easy handling during sequential processing

- Electronically controlled fixed stops:

- Set 2 limit stops at 3 positions on each axis by the push of a button - these buttons are grouped around the feed switch for intuitive control

- This ensures high repeatability during coordinate drilling or pocket cutting, and siginificantly more positions can be set up than on conventional machines

- Electronic spindle load indicator:

- Assists the operator in the most efficient utilization of machine and tool capacities

- Reliable indicator helps avoid damages caused by overloads

Position indicator X.pos 3.2

- The new generation of displays is more powerful, robust, and reliable

- For additional information, see manuals included with the standard equipment

X.pos Plus ; your gain in productivity , quality and comfort

- coordinate value specification

- Bolt circle pattern calculation

- Vibration filter function

- Conversion mm/inch

- 8 display languages

- calculator function

- High-resolution display with excellent readability

- High level of functional reliability under production conditions thanks to state-of-the-art electronics and a particularly robust, completely sealed housing

- During the development and selection of the electronic components, particular attention was paid to ensuring that they were largely insensitive to external interference and kept to a low temperature level

- The display colors of the background and the display can be changed and adapted to the individual wishes of the operator

- Particularly durable and practical keyboard membrane, very pleasant to use

- Furthermore, the display has a radius / diameter switch

- A data backup for the created programs is also possible according to the same principle

- Graphic support with distance-to-go display and sketch display

- Linear and non-linear length correction possible

- Easy installation, simple electrical connection and maintenance-free operation

Technical Details

| Working area | |

|---|---|

| Table dimensions | 1235 mm x 460 mm |

| Table load capacity | 800 kg |

| Number of T-slots | 5 positions |

| T-slots, width | 18 mm |

| T-slots, spacing | 80 mm |

| Travels | |

|---|---|

| Travel X-axis | 900 mm |

| Travel Y-axis | 650 mm |

| Travel Z-axis | 450 mm |

| Milling Head | |

|---|---|

| Speed range (2) | 30-390 / 390-2050 1/min |

| Spindle mount | SK 40 DIN 2080 |

| Swivel angle | 360° |

| Spindle center-to-table distance | 30 mm - 480 mm |

| Rapid feed | |

|---|---|

| Rapid feed X-axis | 2200 mm/min |

| Rapid feed Y-axis | 2200 mm/min |

| Rapid feed Z-axis | 1100 mm/min |

| Feed | |

|---|---|

| Feed speed X-axis | 10 mm/min - 1000 mm/min |

| Feed speed Y-axis | 10 mm/min - 1000 mm/min |

| Feed speed Z-axis | 5 mm/min - 640 mm/min |

| Drive capacity | |

|---|---|

| Motor rating main drive | 7,5 kW |

| Motor rating X axis feed | 3,6 kW |

| Motor rating Y axis feed | 3,6 kW |

| Motor rating Z axis feed | 5,5 kW |

| Motor rating coolant pump | 0,13 kW |

| Measures and weights | |

|---|---|

| Overall dimensions (length x width x height) | 2 m x 2,5 m x 2 m |

| Weight | 4000 kg |

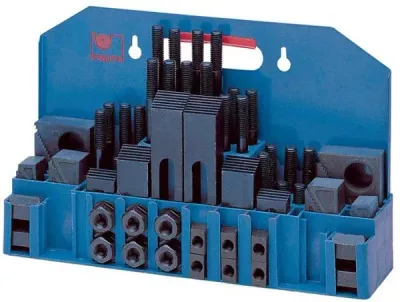

Standard Equipment

- Control panel with X.Pos 3.2 and extended functionsBall screw drives and servo direct drives in all axesAutomatic feed with electric limit switches in all axesElectronic handwheelsAccessories for millingAutomatic central lubricationHeat exchanger for electrical control cabinetProtection shieldCoolant systemLED work lightOperating toolOperator instructions

Optional Equipment

Wide range of tooling options available

Contact us via Email for price details

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.