Knuth UWF 5 Universal Milling Machine ( Part No. 362750 ) Rigid knee and column milling machine with servo drive feed and universal swivel head

Knuth UWF 5 Universal Milling Machine

( Part No. 362750)

Rigid knee and column milling machine with servo drive feed and universal swivel head.

Availability. Currently 9 weeks from receipt of order. Subject to no prior sales.

Highlights

Knuth UWF 5 Universal Milling MachineThis universal milling machine is one of the top models in the UWF series, which is characterized by a large working area, the universal milling head and the horizontal spindle. The more powerful drive, the increased speed range and the infinitely variable servomotor feed expands the range of applications of the UWF 5. Its milling head can be swiveled in two planes and the horizontal spindle has its own drive with finely graduated gear switching. With the extensive equipment, this model is perfect for repair shops as well as training and production departments.

- Universal milling head can be swiveled in 2 levels

- Horizontal spindle with its own drive

- the milling table swivels

- Servo feed in all axes with rapid traverse

- Extensive standard accessories

Details

- Heavy machine frame in cantilever design made of high-strength HT-200 gray cast iron

- Precision-ground guideways, surface-hardened, long-term precise and robust

- Large working area of 1325 x 360 mm and up to 500 kg table load

- Smooth-running, precisely manufactured main spindle gear with hardened and ground gears

- Universal milling head can be swiveled in 2 levels - from horizontal to vertical processing in just a few movements

- By combining both swivel planes, almost any angle in space can be adjusted

- Powerful servo axis motor enables stepless variation of the feeds in all 3 axes

- Telescopic cover in Y-axis protects the feed screw

- Laterally swiveling control panel with integrated position indicator

- 5.5 kW main drive guarantees high torque

- Coolant system and chip tray as standard

3-axis position indicator

- Higher work accuracy

- Lower error rate

- Greater production security

- Significant time savings

- productivity increase

- Optimal readable display

- User-friendly functions

- Clearly arranged keyboard

- Resolution 0.01 / 0.005mm

- coordinate value specification

- Retaining the axis position when the display is switched off

- Bolt circle pattern calculation

- calculator function

- Storage for 10 tools

- Radius / diameter switching

- Conversion mm/inch

- Easy attachment and maintenance-free operation

Technical Details

| WORKSPACE | |

|---|---|

| T-slots, number | 3 pieces |

| table dimensions | 1325mm x 360mm |

| Table load capacity (max.) | 500kg |

| T-slots (width x distance) | 18mm x 80mm |

| TRAVERSE PATHS | |

|---|---|

| X axis travel | 750mm |

| Y axis travel | 280mm |

| Z axis travel | 390mm |

| MILLING HEAD | |

|---|---|

| RPM range levels | 12 |

| speed range | 60 rpm - 1750 rpm |

| spindle mount | ISO 50 |

| swivel angle | 360° |

| Travel upper beam | 550mm |

| Distance spindle center - table | 175mm - 565mm |

| RAPID TRAVERSE | |

|---|---|

| Rapid X axis | 1200mm/min |

| Rapid traverse Y-axis | 800mm/min |

| Rapid Z axis | 600mm/min |

| HORIZONTAL MILLING SPINDLE | |

|---|---|

| Spindle speed (horizontal) levels | 12 |

| Spindle speed (horizontal) | 60 rpm - 1800 rpm |

| spindle mount | ISO 50 |

| unloading | 380mm - 930mm |

| FEED | |

|---|---|

| Feedrate X axis | 30mm/min - 750mm/min |

| Y axis feed rate | 20mm/min - 500mm/min |

| Feedrate Z axis | 15mm/min - 375mm/min |

| DRIVE POWER | |

|---|---|

| Motor power feed X axis | 1.5kW |

| Motor power feed Z-axis | 1.5kW |

| Engine power coolant pump | 0.09kW |

| Motor power horizontal spindle | 5.5kW |

| Motor power vertical spindle | 4kW |

| Motor power feed Y-axis | 1.5kW |

| MASS AND WEIGHT | |

|---|---|

| Dimensions (length x width x height) | 1.8m x 2.1m x 2m |

| Weight | 2850kg |

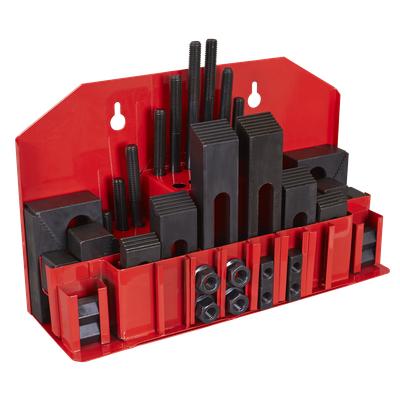

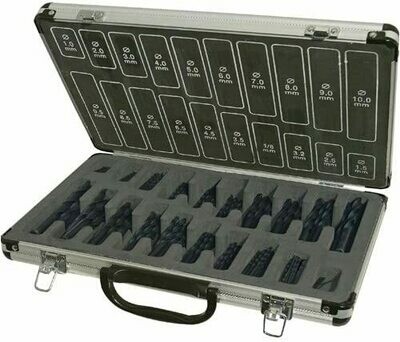

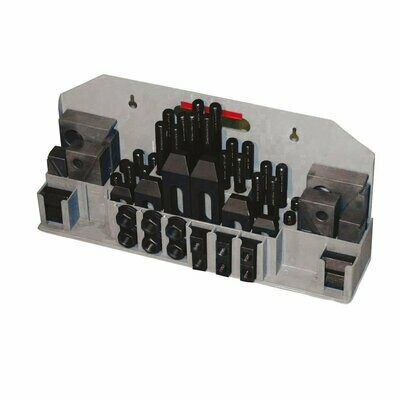

Standard Equipment

- 3-axis position indicator Reducing sleeve

ISO 50 / MK4 Milling arbors

(27, 32 mm)

Counter holder for horizontal milling Collet

chuck ISO 50 incl. collets up to 16 mm (8 pieces)

Coolant system

Work

light Chip tray

Pull

-in rod Operating tools

Operating instructions

Options

Wide range of tooling options available

Contact us via Email for price details

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.