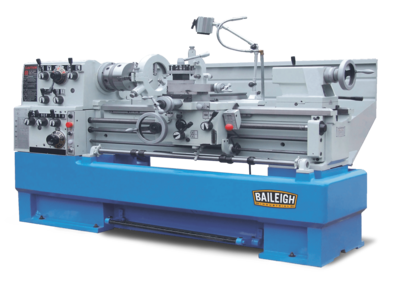

Knuth V-Turn 410 PRO Universal Lathe ( Part No. 300822 ) knuth's bestseller lathe for workshop applications, production and training purposes with extensive standard equipment

Knuth V-Turn 410 PRO Universal Lathe

( Part No. 300822 )

knuth's bestseller lathe for workshop applications, production and training purposes with extensive standard equipment

Ex Stock Availability, 4 weeks lead time to site.

Highlights

Knuth V-Turn 410 PRO Universal Lathe

The newly designed PRO models of the bestseller V-Turn convince with improved ergonomics and more safety. Equipped with an inverter and a high-performance spindle motor, they can easily reach 3,000 revolutions per minute. Workpieces with a small diameter can thus be efficiently machined. However, the models also offer strength and stability for heavier machining. The built-in function of the constant cutting speed, which adapts the spindle speed to the diameter when facing, enables turning results that are comparable to CNC machines to be achieved.

- Ergonomic machine enclosure

- Improved apron auto-feed for easier operation

- Constant cutting speed

- High spindle speed and motor power

Detail

- Incl. 3-axis position indicator with integrated spindle speed display, fully assembled

- The redesigned machine enclosure and added safety features make this machine even more ergonomic, complementing functionality and design

- Constant cutting speed: During face turning, the spindle speed automatically adapts to the changing workpiece diameter – the constant cutting speed at the cutting edge of the turning tool ensures superior turning results with quality comparable to CNC lathes

- A heavily ribbed machine bed, rigid headstock and a massive one-piece cast-iron stand form a solid machine base

- Wide, induction-hardened guideways ensure superior turning results and long life

- Facing and top slides feature adjustable guideways and spindle nuts

- High-precision pre-loaded spindle bearings ensure superior concentricity and load capacity

- A powerful 5.5 kW main spindle motor ensures rapid acceleration and powerful chip removal across the entire speed range

- Back-gearing ensures high torque for highly efficient machining

- Rugged feed switch at the support simplifies operation

- The extensive features of the X.Pos Position Indicator are complemented here with a digital speed indicator and an easy to program auxiliary function

- More accuracy

- Lower error rate

- Increased productivity

- Resulting in valuable time savings

- For increased productivity

- Easy to read display

- Operator-specific features

- Convenient keyboard layout

- Resolution: 0.01/ 0.005 mm

- Default coordinates

- Axis position is maintained when display is turned off

- Storage for 10 tools

- Radius / diameter toggle

- Mm/inch conversion

- Display for top (Z0) and box way slide (Z1) both separate and in differential / cumulative mode for lathes

3-axis position indicator

Technical Details

| WORKING AREA | |

|---|---|

| Center width | 1000 mm |

| Center height | 205 mm |

| Turning diameter over bed | 380 mm |

| Turning diameter over gap bridge | 580 mm |

| Turning-Ø over support | 255 mm |

| Gap bridge length | 250 mm |

| Bed width | 250 mm |

| TRAVELS | |

|---|---|

| Travel X-axis | 210 mm |

| Travel Z1-axis | 140 mm |

| Swing range of top slide | ± 45° |

| HEADSTOCK | |

|---|---|

| Speed range, high | 550 1/min - 3000 1/min |

| Speed range, low | 30 1/min - 550 1/min |

| Spindle bore | 52 mm |

| Spindle mount | Camlock D1-6 |

| Spindle taper | 6 MT |

| FEED | |

|---|---|

| Feed X-axis | 0,013 mm/R - 0,45 mm/R |

| Feed Z-axis | 0,026 mm/R - 0,9 mm/R |

| TAPPING | |

|---|---|

| Tapping, metric | (39) 0,2-14 mm |

| Tapping, diametric | (21) 8-44 DP |

| Tapping, module | 0,3 mm - 3,5 mm |

| Tapping, whitworth | (45) 2-72 TPI |

| TAILSTOCK | |

|---|---|

| Tailstock quill diameter | 50 mm |

| Tailstock taper | 4 MT |

| Tailstock quill stroke | 120 mm |

| Tailstock traverse adjustment | ± 13 mm |

| DRIVE CAPACITY | |

|---|---|

| Motor rating main drive | 5,5 kW |

| MEASURES AND WEIGHTS | |

|---|---|

| Overall dimensions (length x width x height) | 1,94 m x 1,94 m x 1,94 m |

| Weight | 1210 kg |

Standard Equipment

3-axis position indicator, X.pos 3.2 VC

4-jaw face plate chuck Ø 250 mm

face plate Ø 350 mm

change gears

quick change tool holder head WB

quick change tool holder WBD 25120

coolant system

steady rest

chip tray

fixed splash guard (wall)

Support shield

follow rest

turret stop

micrometer stop

foot brake pedal

chuck guard

LED- worklight

operating tools

dead center

reducing Sleeve

operating tools

operator instructions

Optional Tooling

Wide range of tooling options available

Contact us via Email for price details

Operator Training

Operator training available in showroom subject to quotation

prior to delivery. Email us to outline your needs.

Shipping

Fully inclusive shipping rates covering transportation, import customs documentation, duties

quoted for inclusion at time of order for UK mainland sites. Northern Ireland destinations, Islands

and other remote sites should seek advice prior to order via email. Clients will be responsible for

their own site offload and siting at point of use.

Finance Availability

Looking to finance your equipment?

We have access to a variety of funding sources who will look sympathetically

at requests for funding finance.

These include leading merchant banks such as asset finance specialists Close Brothers and Lombard.

The financial services division of Siemens will consider HP on the investment. Subject to Status.

On an investment of this nature with a long delivery lead time we can also look at providing a staged payment schedule.

We will confirm this with you at time of order.

The certificate holder's Management System corresponds to standard ISO 9001:2015.

Get in touch

We will get back to you as soon as possible

Oops, there was an error sending your query.

Please try again later