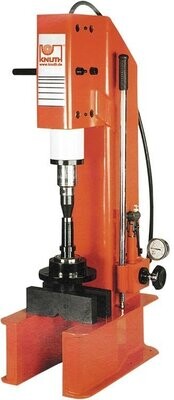

Sicmi Automatic Hydraulic Press For Sheet Metal Bending – PDL -A ( 40 - 100 Ton rated options)

Sicmi Automatic Hydraulic Press For Sheet Metal Bending - PDL-A

( 40 - 100 Ton rated options)

Delivery Lead Time / 75 Days to UK Mainland Sites from Order.

Highlights

Automatic PDL - A Models

Hydraulic bending press machine with monolithic frame specific for sheet metal.

The PDL hydraulic press is made with a highly rigid electro-welded steel carpentry structure and has an upper mobile support and a lower fixed surface.

The attachments and fixing brackets for the punch are arranged on the upper mobile part, while the brackets for the sheet metal bending die are installed on the lower platform.

The electro-hydraulic press is equipped with front supports for positioning the metal piece to be worked and are equipped with a millimeter rod.

A rear protective metal mesh is also provided to allow operators to work in total safety.

The approach speed of the hydraulic cylinder is under 10 mm/sec and this, based on safety regulations, allows the operator to have his hands free and to be able to move the sheet metal during the press processing phases.

The PDL hydraulic bending press machine is available in semi-automatic and automatic versions.

Automatic with double pedals

In the automatic version, the operation of the PDL hydraulic press occurs with the use of double pedals. In this model, the automatic lifting of the cylinder is foreseen, the stroke of which is adjustable using the appropriate sensors.

The machine is also supplied with an emergency button on the pedal, or with an anti-shock system which blocks the press with the increase in pressure exerted by the operator's foot on the pedal.

Furthermore, the installation of a switch is designed to be able to use the machine also in manual mode, which therefore provides for the descent of the cylinder, but without its automatic ascent.

Range of Sizes Available

PDL 40A 40 Ton Rated

Stanchions Distance 900 mm - Punch support length 835 mm

PDL 70A 70 Ton Rated

Stanchions Distance 900 mm - Punch support length 835 mm

PDL 100A 100 Ton Rated

Stanchions Distance 1050 mm - Punch support length 1000 mm

Standard Equipment

- Pair of Front Support Plates equipped with mm measure & adjustment

- Maximum pressure valve

- Anchoring hydraulic pipes

- Anti Fall & Anti Exposion Valves

- Anchoring electrical cables

- Stop flex anchor

- Current transformer

- Cylinder limit switches

Pedal control with automatic return of cylinder- regulation of the stroke with microns

for up and down. Monolithic frame, Cylinder stroke 500 mm.

Optional Equipment

1/ Pair of Rear Supports

2/ Frontal light curtain 1000 mm high

Photoelectric barriers are safety tools that create an invisible protective barrier through the use of infrared rays.

They are configured to immediately stop the pressing process if the operator or any object comes between the photocells.

The barriers are protected by sheet metal and aluminum mesh and this configuration also allows the minimum distance from the end of the work surface to be respected.

Thanks to the photoelectric barriers, a protected work area is created and this makes it possible to operate the hydraulic press with a single button (or with a pedal), without the need for simultaneous two-hand control.

3/ Digital Control with Siemens Touchscreen Display KTP 700 Basic

With the Siemens touchscreen display you can set the following parameters:

- Maximum upstroke and downstroke of the hydraulic cylinder

- Pressure maintenance time on the lower platform

- Work pressure

- Decompression time

- Piece counter

- Prestop ascent/descent: function that allows you to stop the ascent or descent before reaching the quota, thus eliminating errors caused by speed and cavitation due to the weight of the mould. It guarantees an accuracy of 0.1mm.

- Alarm management

There is the possibility of storing 100 different programs with a progressive number.

You can choose between manual and automatic modes.

In automatic mode the cylinder rises automatically.

The stroke is read using a wire encoder.

The pressure is read using a transducer installed on the hydraulic control unit.

Warranty

Sicmi 1 year guarantee as standard

Founded in 1983, Sicmi is now known nationally and internationally as a leading brand of press automation.

Quality System UNI EN ISO 9001: 2008

Get in touch

We will get back to you as soon as possible

Oops, there was an error sending your query.

Please try again later