Sicmi Hydraulic workshop press with servomechanical handwheel – PSV ( 30/50/70 Ton rated options)

Sicmi Hydraulic workshop press with servomechanical handwheel – PSV

( 30/50/70 Ton rated options)

Delivery Lead Time / 75 Days to UK Mainland Sites from Order.

Highlights

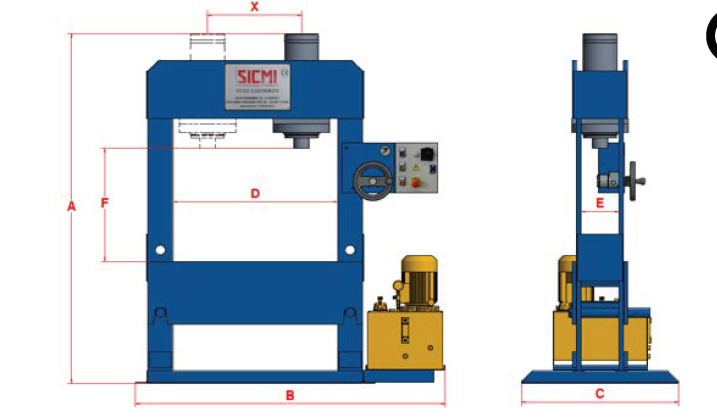

The hydraulic workshop press with servomechanical handwheel for cylinder adjustment, PSV model, is particularly suitable for carrying out sheet metal straightening work, for inserting bushings or metal inserts.

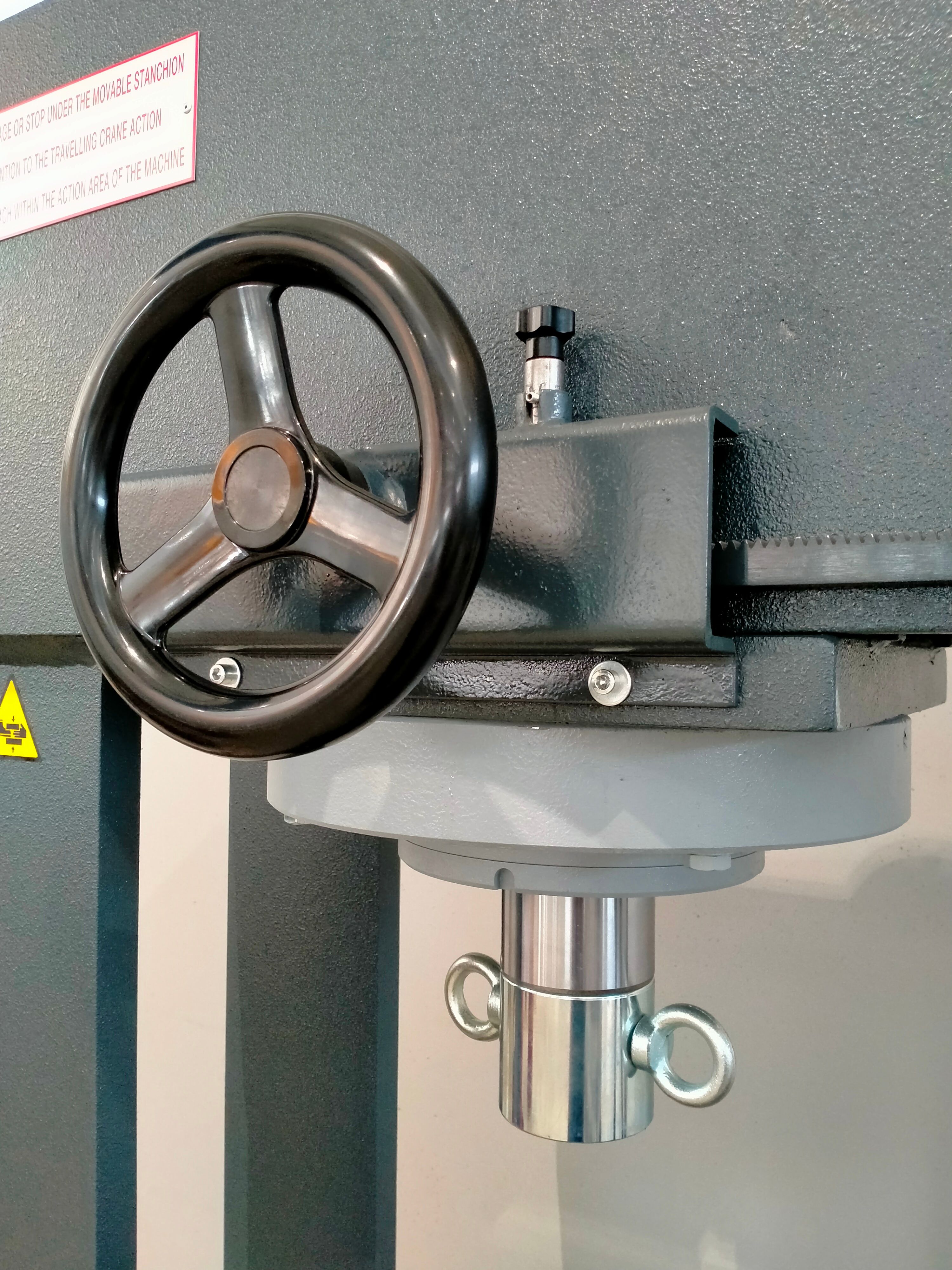

The descent and ascent of the cylinder are managed by a handwheel operated with a servomechanism, which allows the position of the cylinder to be adjusted to the hundredth of a millimetre, thus guaranteeing absolute precision.

The cylinder stroke is 350mm and exerts a maximum pressure of 270 bar. Since the approach speed of the cylinder is equal to or less than 10 mm/sec, this allows the use of the electro-hydraulic press with only one hand by the operator.

The platform is mobile and its height movement takes place through the use of the main cylinder, thus facilitating the operations of tooling and pressing of the sheet metal.

The hydraulic workshop press with servomechanical handwheel is also available in the version with transversal mobile cylinder, which, with the aid of a handwheel, allows the main cylinder to be moved transversally. This solution therefore allows you to always work in the center of the cylinder axis, thus avoiding processes that could damage the hydraulic press.

The correct positioning and locking of the cylinder in the desired position are guaranteed by a specially designed system.

The frame of the PSV hydraulic workshop press is made with a highly rigid electro-welded steel carpentry structure, specifically designed to guarantee maximum sturdiness and stability.

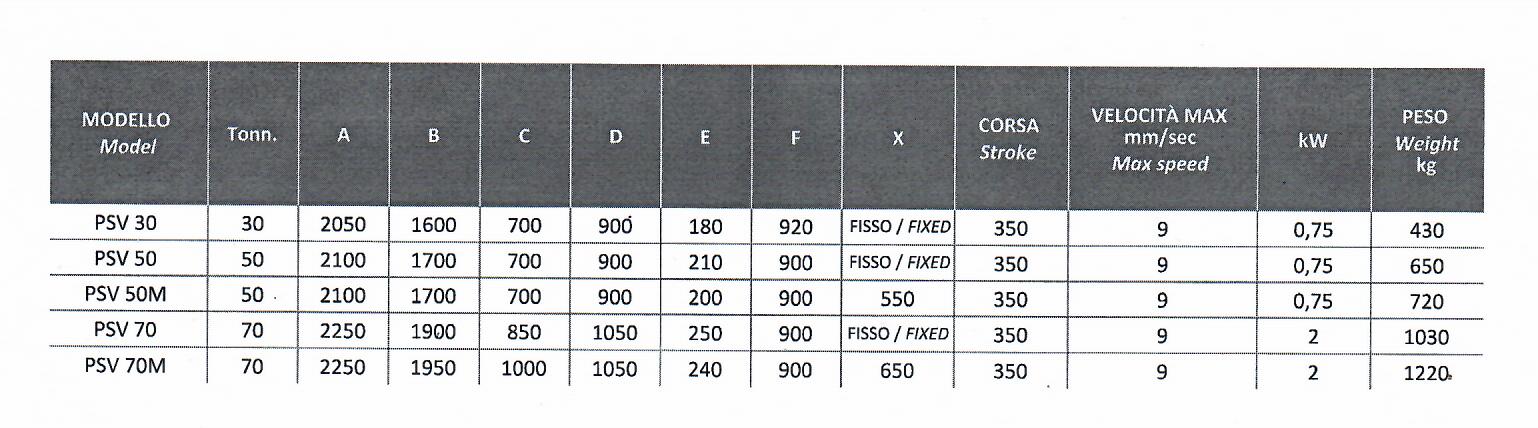

Range of Sizes Available

PSV 30 30 Ton Rated

Stanchions Distance 900 mm - Fixed Cylinder

PSV 50 50 Ton Rated

Stanchions Distance 900 mm - Fixed Cylinder

PSV 50 M 50 Ton Rated

Stanchions Distance 900 mm - Transversal movable cylinder with manual control

PSV 70 70 Ton Rated

Stanchions Distance 1050 mm - Fixed Cylinder

PSV 70 M 70 Ton Rated

Stanchions Distance 1050 mm - Transversal movable cylinder with manual control

Standard Accessories:

- Support Plate

- Pair of V Shaped Prisms

Technical Details

Optional

Cylinder movement with lever & handwheel

The hydraulic workshop press, PSV model, can be equipped with the double control with lever and handwheel for cylinder adjustment.

Through the use of the lever, the cylinder descends at a speed below 10 mm/sec and therefore allows a rapid approach of the piston to the material that must be pressed.

When the cylinder is close to the piece to be worked, the operator can use the handwheel which allows an extremely controlled descent of the piston and this allows absolutely precise machining.

Click below to watch the video of this optional feature.

Warranty

Sicmi 1 year guarantee as standard

Founded in 1983, Sicmi is now known nationally and internationally as a leading brand of press automation.

Quality System UNI EN ISO 9001: 2008

Get in touch

We will get back to you as soon as possible

Oops, there was an error sending your query.

Please try again later